- Description

INTENSIVE COOLING CHAMBERS

Intensive cooling chambers present a new dawn for the work of meat processing enterprises.

The benefits of this chambes:

- an increase in the % of product yield compared to the traditional way of cooling;

- an increase in terms of product realization by means of rapid temperature drop.

- reduction of the the area storage premises of the company.

- reduction in the time from the moment of thermal treatment up to products packing and their shipment.

The technological process is fully automated and controlled by a multi-functional management controller “Polytherm-24".

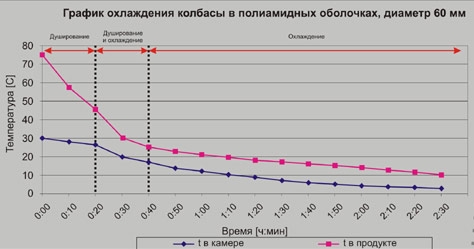

The process of intensive cooling is carried out in three stages:

- water cooling by means of powerful sprayer up to the temperature of 45°C*;

- water cooling with the turned on cooling unit to a temperature of 25°C**;

- cooling by means of refrigerated air up to a temperature of 10°C.

*, ** - the value of the temperatures is determined by the diameter of sausage limks and the type of the casing

Technical specigications of the intensive cooling chamber:

| Dimensional specifications, mm width, height, depth |

Electric power, kW |

In the cold power, kW | Refreezable gel-type packet | Water consumprion, l per h | The Diameter of the inlet pipe, water | Conditional load. kg |

|

|

Thermix 400I

|

1500х2820х2500 | 20 | 28 | R22 | 2000 | 1'' | 400 |

|

Thermix 600I

|

1500х2820х3700 | 30 | 45 | R22 | 3000 | 1,5'' | 600 |

|

Thermix 800I

|

1500х2820х4900 | 40 | 60 | R22 | 4000 | 2'' | 800 |

To request or obtain detailed information, call:br>

+38 (0567) 32-43-00

Mon—Fri, 09:00—18:00

Or fill out the form below and we will contact you as soon as possible.

Ask a Question